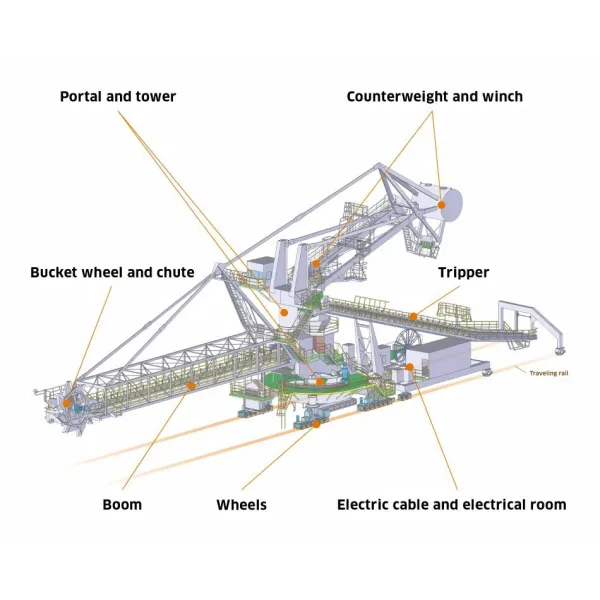

Stacker-reclaimers are widely used in the stacking and reclaiming of bulk materials (coal, ore, etc.). Stacker-reclaimers are mainly composed of steel structure,arm belt conveyor,tail car,luffing mechanism, slewing mechanism, trolley running mechanism, dust removal system, bucket wheel device, electrical equipment and other necessary safety and auxiliary facilities. Its arm can rotate, luff, and telescope, and the head rotates the bucket wheel to dig materials. According to its different functions, it can be divided into: stacker, bucket wheel reclaimer, bucket wheel stacker-reclaimer.

Main standards cited: GB/T14695-93 "Arm-type bucket wheel stacker-reclaimer type parameters", JB/T7326-94 "Bucket wheel stacker-reclaimer safety specifications", JB/T7328-94 "Bucket wheel stacker-reclaimer acceptance technical specifications", GB3811-2008 "Crane design specifications", GB6067-85 "Crane safety specifications".

Feature of Stacker-Reclaimers

Efficient Continuous Operation: The integration of a boom conveyor and slewing mechanism enables seamless switching between stacking and reclaiming, significantly improving operational efficiency.

High Flexibility: The boom can rotate, luff, and telescopically extend, adapting to material piles of varying heights and angles for broad coverage.

Automated Control: Equipped with an intelligent control system, it supports remote operation, automatic positioning, and flow rate adjustment, minimizing manual intervention.

Robust Performance in Harsh Environments: Reinforced structural design with wind-resistant and dust-proof features ensures stable operation in high-dust, high-wind, and other challenging conditions.

Energy Efficiency and Environmental Protection: Utilizes low-energy drive systems, with select models incorporating spray dust suppression systems to reduce environmental pollution.

Application Fields of Stacker-Reclaimers

Thermal Power Plants: Used for coal stacking and reclaiming to ensure uninterrupted fuel supply for boilers.

Ports and Terminals: Handles bulk cargo such as iron ore, coal, and grain, enhancing port handling capacity.

Iron & Steel and Metallurgical Industries: Manages storage and transportation of raw materials like iron ore, coke, and limestone.

Coal Mines: Performs large-scale coal stacking, reclaiming, and blending operations in coal storage yards.

Building Materials and Chemical Sectors: Facilitates storage management of cement raw materials, fertilizers, aggregates, and other bulk commodities.

Composition of stacker-reclaimer

I. Main Structure

1. Gantry Frame

Function: Serves as the supporting framework of the equipment, carrying the boom, drive systems, and other components to ensure overall stability and load-bearing capacity.

Components: Includes main beams, support legs, counterweights, etc. Some models adopt full-gantry or semi-gantry designs.

2. Boom

Function: The core component for mounting the conveyor, enabling material stacking and reclaiming coverage through telescoping, luffing, and slewing motions.

Types: Fixed boom or telescopic boom, with some models featuring bidirectional belts (dual-mode for stacking/reclaiming).

II. Motion and Drive Systems

1. Slewing Mechanism

Function: Drives the boom to rotate horizontally (typically 360°), expanding the working radius and precisely positioning the material pile.

Components: Slewing bearing, drive motors, gearboxes, and control systems.

2. Luffing Mechanism

Function: Adjusts the boom's elevation angle to accommodate material piles of varying heights, avoiding collisions with the ground or other equipment.

Implementation: Hydraulic cylinder drives or wire rope winch systems.

3. Travel Mechanism

Function: Drives the equipment along tracks or ground to cover the entire stockyard area.

Types: Rail-mounted (common in large stockyards) or crawler-type (suitable for flexible sites).

III. Material Handling System

1. Boom Conveyor

Function: Transports materials to the top of the pile during stacking and transfers materials from the pile to downstream conveyors via scrapers or bucket wheels during reclaiming.

Design Features: Bidirectional operation, with some models equipped with reversible belts or dual-belt configurations.

2. Reclaiming Device

Types:

Bucket Wheel Reclaimer: Excavates materials via a rotating bucket wheel, suitable for hard bulk materials (e.g., ores, coal).

Scraper Reclaimer: Uses scraper chains for layered reclaiming, ideal for loose materials (e.g., grains, fertilizers).

IV. Control and Safety Systems

1. Intelligent Control System

Function: Integrates PLCs, sensors, and automation software to enable stacking/reclaiming path planning, flow monitoring, fault diagnostics, and remote operation.

2. Safety Protection Devices

Components:

Limit Switches: Prevent the boom from exceeding rotational or luffing ranges.

3. Anti-Collision System: Monitors obstacles via LiDAR or cameras.

Wind Speed Monitor: Automatically locks the equipment during strong winds to prevent tipping.

V. Auxiliary Systems

1. Spray Dust Suppression System

Function: Sprays mist during stacking/reclaiming to reduce dust dispersion.

2. Lubrication System

Function: Automatically supplies lubricant to critical components (e.g., slewing bearings, gears) to extend service life.

Port Cranes

Port Cranes  Overhead Cranes

Overhead Cranes  Gantry Cranes

Gantry Cranes  Rubber-Tired Gantry Cranes

Rubber-Tired Gantry Cranes  Jib Cranes

Jib Cranes  Bridge Beam Launcher

Bridge Beam Launcher  Light-duty Cranes

Light-duty Cranes  Electric Hoists

Electric Hoists  Electric Winch

Electric Winch  Electric Flat Car

Electric Flat Car  Crane Accessories

Crane Accessories  Hydraulic Lifting Platform

Hydraulic Lifting Platform  General Manufacturing

General Manufacturing  Heavy Machinery Manufacturing

Heavy Machinery Manufacturing  Bulk Cargo Yard

Bulk Cargo Yard  Metallurgical Industry

Metallurgical Industry  Power Industry

Power Industry  Hydraulic Engineering

Hydraulic Engineering  Railway/Rail Transit

Railway/Rail Transit  Port Terminal

Port Terminal  Construction and Engineering

Construction and Engineering  Shipbuilding

Shipbuilding  Waste Recycling

Waste Recycling