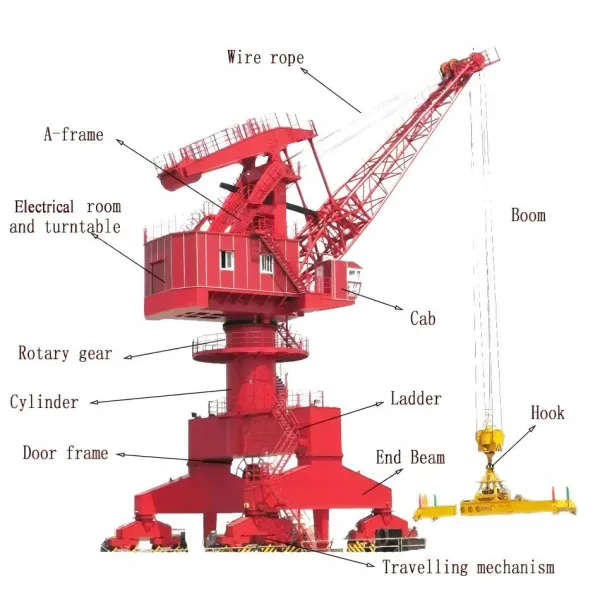

Single jib portal crane is mainly composed of steel structure, lifting mechanism, luffing mechanism, slewing mechanism, trolley running mechanism, hoisting device (grab, container hoist, electromagnetic disk, hook), electrical equipment and other necessary safety and auxiliary equipment. The steel structure is mainly composed of boom, herringbone, slewing platform and gantry. It is used for loading and unloading of bulk materials (coal, ore, etc.) and various sundries at docks, and shipyard operations at shipyards.

Characteristics of the MQC Type Single Jib Portal Crane

The single-jib portal crane is distinguished by its structural compactness and operational efficiency. Its single-jib design simplifies mechanical construction, reduces self-weight and equipment costs, while an articulated luffing mechanism enables wide-range elevation adjustments to cover an extended working radius. Equipped with independent hoisting, slewing, and travel systems, it significantly enhances loading/unloading efficiency. The crane is engineered for high-frequency, heavy-load continuous operations and features robust wind resistance, making it suitable for outdoor environments.

Applications of the MQC Type Single Jib Portal Crane

This model is primarily deployed in ports, railway freight yards, large logistics hubs, and shipyards. In port terminals, it handles container yard handling and bulk cargo grab operations for ships. At railway hubs, it facilitates bulk cargo transfer between trains. In shipbuilding, it supports section assembly and heavy component lifting. Its flexibility and high load capacity also make it vital for bridge construction and power plant equipment installation, solidifying its role as indispensable equipment in modern industrial logistics and heavy engineering.

-

Portal Frame The main support structure that forms the base of the crane, allowing it to span a specific area.The portal usually has legs that provide clearance for vehicles or cargo to pass underneath.

Portal Frame The main support structure that forms the base of the crane, allowing it to span a specific area.The portal usually has legs that provide clearance for vehicles or cargo to pass underneath. -

Electrical Room Houses power distribution cabinets, control cabinets, and electrical components. Responsible for power distribution, signal transmission, and system control, ensuring stable and reliable operation of the entire system.

Electrical Room Houses power distribution cabinets, control cabinets, and electrical components. Responsible for power distribution, signal transmission, and system control, ensuring stable and reliable operation of the entire system. -

Cable Reel Automatically retracts or deploys power cables to maintain continuous electrical supply during crane movement. Prevents cable abrasion or entanglement risks caused by dragging on the ground.

Cable Reel Automatically retracts or deploys power cables to maintain continuous electrical supply during crane movement. Prevents cable abrasion or entanglement risks caused by dragging on the ground. -

Operator's Cab Central control hub equipped with consoles, monitoring screens, and safety devices. Provides a panoramic view and centralized control over travel, hoisting, luffing, and other operations.

Operator's Cab Central control hub equipped with consoles, monitoring screens, and safety devices. Provides a panoramic view and centralized control over travel, hoisting, luffing, and other operations. -

Slewing Mechanism Drives 360° horizontal rotation of the crane's upper structure (including the boom, operator's cab, etc.), expanding operational coverage and enabling flexible adjustment of lifting direction.

Slewing Mechanism Drives 360° horizontal rotation of the crane's upper structure (including the boom, operator's cab, etc.), expanding operational coverage and enabling flexible adjustment of lifting direction. -

Cylinder The cylinder is connected with the running mechanism, the height can be customized,and it is made of high-quality steel.

Cylinder The cylinder is connected with the running mechanism, the height can be customized,and it is made of high-quality steel. -

Lifting Attachment Configured for specific cargo types (e.g., hooks, grabs, or container spreaders). Directly secures or grips cargo to ensure safe and efficient loading/unloading.

Lifting Attachment Configured for specific cargo types (e.g., hooks, grabs, or container spreaders). Directly secures or grips cargo to ensure safe and efficient loading/unloading.

Port Cranes

Port Cranes  Overhead Cranes

Overhead Cranes  Gantry Cranes

Gantry Cranes  Rubber-Tired Gantry Cranes

Rubber-Tired Gantry Cranes  Jib Cranes

Jib Cranes  Bridge Beam Launcher

Bridge Beam Launcher  Light-duty Cranes

Light-duty Cranes  Electric Hoists

Electric Hoists  Electric Winch

Electric Winch  Electric Flat Car

Electric Flat Car  Crane Accessories

Crane Accessories  Hydraulic Lifting Platform

Hydraulic Lifting Platform  General Manufacturing

General Manufacturing  Heavy Machinery Manufacturing

Heavy Machinery Manufacturing  Bulk Cargo Yard

Bulk Cargo Yard  Metallurgical Industry

Metallurgical Industry  Power Industry

Power Industry  Hydraulic Engineering

Hydraulic Engineering  Railway/Rail Transit

Railway/Rail Transit  Port Terminal

Port Terminal  Construction and Engineering

Construction and Engineering  Shipbuilding

Shipbuilding  Waste Recycling

Waste Recycling