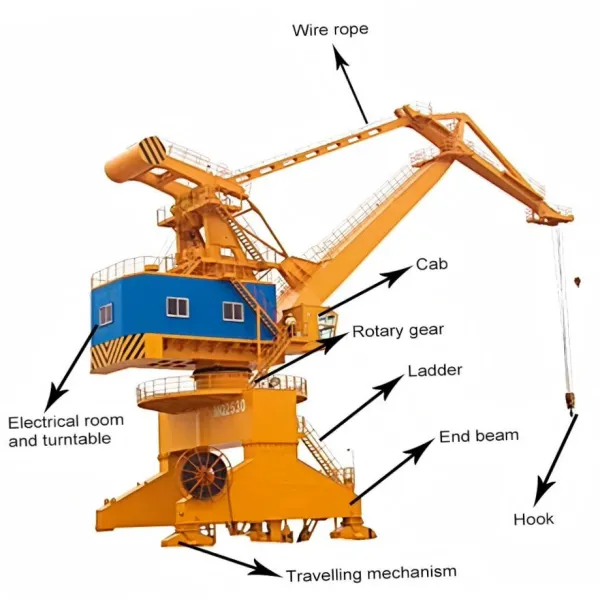

MQ type Four-link portal cranes are widely used in port loading and unloading, shipbuilding and repairing, and material handling in the steel and metallurgical industry. They are mainly composed of steel structure, lifting mechanism, luffing mechanism, slewing mechanism, trolley running mechanism, hoisting device (grab, container hoist, hook, electromagnetic disk), electrical equipment and other necessary safety and auxiliary equipment. The steel structure consists of boom, herringbone, slewing platform and portal.

Characteristics of the MQ type Four-link Portal Crane

Optimized Motion Trajectory

The four-bar linkage mechanism automatically compensates for height variations of the lifting attachment during luffing, achieving quasi-horizontal movement of the load. This minimizes cargo sway, making it ideal for fragile goods or high-precision lifting operations.

High Stability

The synergy between the four-bar linkage and counterweight system effectively distributes load stresses, enhances anti-overturning capability, and ensures reliable performance under heavy loads or complex working conditions.

Large Coverage Range

Featuring a long boom design and large-angle luffing capability, it covers a vast working radius-from dense stacking areas near the base to distant ship holds.

High-Efficiency Drive System

Independently controlled hoisting, luffing, slewing, and travel mechanisms enable multi-action coordination, significantly improving loading/unloading efficiency.

Environmental Adaptability

The portal-type chassis design combined with wind-resistant anchoring devices ensures stable operation in outdoor environments, even under strong winds or tidal variations.

Applications of the MQ type Four-link Portal Crane

Bulk Cargo Terminals: Continuous handling of coal, ore, and other bulk materials using grabs or buckets, enabling efficient ship-to-shore transfer.

Steel and Heavy Industries: Lifting rolling mill equipment, large castings, and high-temperature ladles, meeting demands for precision and safety in heavy material handling.

Power Plants and Energy Sector: Transporting power generator components, boiler systems, and wind turbine blades, ensuring accurate positioning of oversized equipment at height.

Container Hubs: Supporting medium-to-long-distance lifting in container yards, particularly suited for automated terminals requiring cargo stability.

Specialized Engineering: Critical for bridge component assembly and ship block joining, leveraging its high load capacity and trajectory control advantages.

-

Portal Frame The main support structure that forms the base of the crane, allowing it to span a specific area.The portal usually has legs that provide clearance for vehicles or cargo to pass underneath.

Portal Frame The main support structure that forms the base of the crane, allowing it to span a specific area.The portal usually has legs that provide clearance for vehicles or cargo to pass underneath. -

Electrical Room Houses power distribution cabinets, control cabinets, and electrical components. Responsible for power distribution, signal transmission, and system control, ensuring stable and reliable operation of the entire system.

Electrical Room Houses power distribution cabinets, control cabinets, and electrical components. Responsible for power distribution, signal transmission, and system control, ensuring stable and reliable operation of the entire system. -

Slewing Mechanism Drives 360° horizontal rotation of the crane's upper structure (including the boom, operator's cab, etc.), expanding operational coverage and enabling flexible adjustment of lifting direction.

Slewing Mechanism Drives 360° horizontal rotation of the crane's upper structure (including the boom, operator's cab, etc.), expanding operational coverage and enabling flexible adjustment of lifting direction. -

Operator's Cab Central control hub equipped with consoles, monitoring screens, and safety devices. Provides a panoramic view and centralized control over travel, hoisting, luffing, and other operations.

Operator's Cab Central control hub equipped with consoles, monitoring screens, and safety devices. Provides a panoramic view and centralized control over travel, hoisting, luffing, and other operations. -

Cable Reel Automatically retracts or deploys power cables to maintain continuous electrical supply during crane movement. Prevents cable abrasion or entanglement risks caused by dragging on the ground.

Cable Reel Automatically retracts or deploys power cables to maintain continuous electrical supply during crane movement. Prevents cable abrasion or entanglement risks caused by dragging on the ground. -

Cylinder The cylinder is connected with the running mechanism, the height can be customized, and it is made of high-quality steel.

Cylinder The cylinder is connected with the running mechanism, the height can be customized, and it is made of high-quality steel. -

Lifting Attachment Configured for specific cargo types (e.g., hooks, grabs, or container spreaders). Directly secures or grips cargo to ensure safe and efficient loading/unloading.

Lifting Attachment Configured for specific cargo types (e.g., hooks, grabs, or container spreaders). Directly secures or grips cargo to ensure safe and efficient loading/unloading.

Port Cranes

Port Cranes  Overhead Cranes

Overhead Cranes  Gantry Cranes

Gantry Cranes  Rubber-Tired Gantry Cranes

Rubber-Tired Gantry Cranes  Jib Cranes

Jib Cranes  Bridge Beam Launcher

Bridge Beam Launcher  Light-duty Cranes

Light-duty Cranes  Electric Hoists

Electric Hoists  Electric Winch

Electric Winch  Electric Flat Car

Electric Flat Car  Crane Accessories

Crane Accessories  Hydraulic Lifting Platform

Hydraulic Lifting Platform  General Manufacturing

General Manufacturing  Heavy Machinery Manufacturing

Heavy Machinery Manufacturing  Bulk Cargo Yard

Bulk Cargo Yard  Metallurgical Industry

Metallurgical Industry  Power Industry

Power Industry  Hydraulic Engineering

Hydraulic Engineering  Railway/Rail Transit

Railway/Rail Transit  Port Terminal

Port Terminal  Construction and Engineering

Construction and Engineering  Shipbuilding

Shipbuilding  Waste Recycling

Waste Recycling