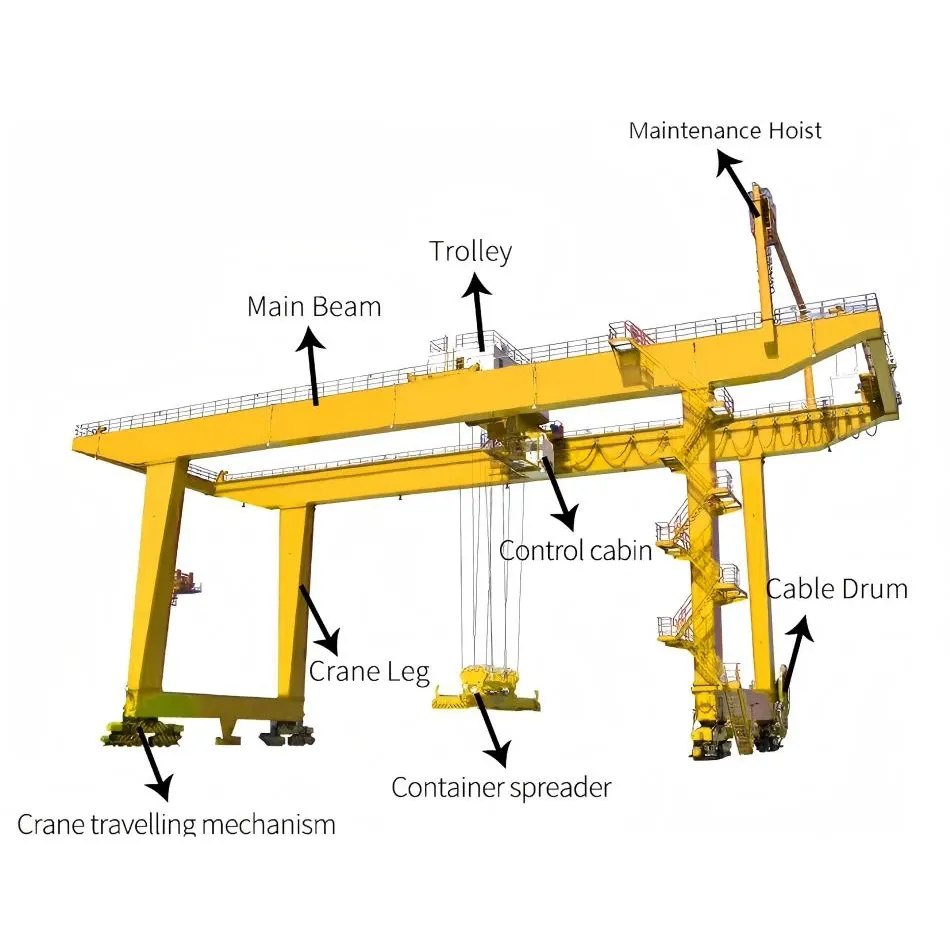

RMG Type Rail Mounted Container Gantry Crane is widely used in port terminals, container yards, and railway freight stations. It operates on fixed tracks and is designed to load, unload, move, and stack 20ft, 40ft, and 45ft ISO-standard containers.

Features:

RMG Type Rail Mounted Container Gantry Crane exhibits the following characteristics:

High structural stability and strong wind resistance, ensuring reliable operation in harsh weather conditions.

Exceptional load capacity and large-span design, capable of handling heavy containers (typically 40-100 tons) across spans up to 30-50 meters.

High operational speed and handling efficiency, with travel speeds of 30-60 m/min and hoisting speeds of 20-40 m/min, significantly boosting container throughput.

Energy efficiency and environmental compliance, utilizing electric drive systems (powered by rail supply or cable reel systems) with zero exhaust emissions and low noise levels, fully complying with green port initiatives.

Applications:

RMG Type Rail Mounted Container Gantry Crane is widely deployed in:

Container ports and storage yards – Optimizing high-density stacking (5-8 tiers) and rapid transshipment operations.

Rail freight hubs – Enabling seamless intermodal logistics between trains, trucks, and vessels.

Automated terminals – Integrating with Terminal Operating Systems (TOS) and Autonomous Guided Vehicles (AGVs) to achieve fully automated, high-throughput workflows.

As a mission-critical asset, Rail Mounted Gantry Crane serve as the backbone of modern container terminals, delivering precision, scalability, and sustainability for large-scale, well-planned logistics hubs.

-

Trolley Smooth running, no rail gnawing low noise safe and reliable

Trolley Smooth running, no rail gnawing low noise safe and reliable -

Container SpreaderMechanical/hydraulic telescopic mechanism (20ft-45ft range) adapts to various container sizes.Easy operation, high efficiency—widely used in port cranes.

Container SpreaderMechanical/hydraulic telescopic mechanism (20ft-45ft range) adapts to various container sizes.Easy operation, high efficiency—widely used in port cranes. -

Crane Cabin Contro: lHigh-strength frame: high-quality profile welded.High-quality cold-rolled plate: CNC-machined.Interior: fire/heat/sound insulation lining; decorated with MDF/aluminum-plastic panel or thin steel plate riveting.

Crane Cabin Contro: lHigh-strength frame: high-quality profile welded.High-quality cold-rolled plate: CNC-machined.Interior: fire/heat/sound insulation lining; decorated with MDF/aluminum-plastic panel or thin steel plate riveting. -

Door Frame It is composed of main girder, end beam, outrigger and lower beam, and it is the main bearing structure. They are divided into cantilevers and no cantilevers.

Door Frame It is composed of main girder, end beam, outrigger and lower beam, and it is the main bearing structure. They are divided into cantilevers and no cantilevers. -

Crane Trolley: Two independent winch systems (hoisting/opening-closing drums) + wire ropes.Coordinated/alternating control enables grab descent, grabbing, hoisting & unloading.

Crane Trolley: Two independent winch systems (hoisting/opening-closing drums) + wire ropes.Coordinated/alternating control enables grab descent, grabbing, hoisting & unloading.

Port Cranes

Port Cranes  Overhead Cranes

Overhead Cranes  Gantry Cranes

Gantry Cranes  Rubber-Tired Gantry Cranes

Rubber-Tired Gantry Cranes  Jib Cranes

Jib Cranes  Bridge Beam Launcher

Bridge Beam Launcher  Light-duty Cranes

Light-duty Cranes  Electric Hoists

Electric Hoists  Electric Winch

Electric Winch  Electric Flat Car

Electric Flat Car  Crane Accessories

Crane Accessories  Hydraulic Lifting Platform

Hydraulic Lifting Platform  General Manufacturing

General Manufacturing  Heavy Machinery Manufacturing

Heavy Machinery Manufacturing  Bulk Cargo Yard

Bulk Cargo Yard  Metallurgical Industry

Metallurgical Industry  Power Industry

Power Industry  Hydraulic Engineering

Hydraulic Engineering  Railway/Rail Transit

Railway/Rail Transit  Port Terminal

Port Terminal  Construction and Engineering

Construction and Engineering  Shipbuilding

Shipbuilding  Waste Recycling

Waste Recycling