A hydroelectric power station gantry crane is a heavy-duty lifting equipment specifically designed for hydropower projects. It is primarily used for the installation, maintenance, and repair of hydraulic gates, hoisting turbine generators, and servicing trash racks. Its large-span gantry structure spans across dam crests or plant rail tracks, accommodating complex spatial layouts and high-load demands.

Key Features of hydroelectric power station gantry cranes

Large Span and High Load Capacity

Main girder spans range from 30–60 meters, with a maximum lifting capacity of 500 tons (e.g., specialized models for gate installation).

Utilizes box girders or truss girders to handle large hydropower components.

Precision Positioning and Anti-Sway Control

Equipped with variable frequency speed regulation systems (0.1–10 m/min stepless speed) and laser positioning systems, achieving hook positioning accuracy of ±2 mm.

Ideal for high-precision alignment in gate slots and turbine shaft bores.

Enhanced Environmental Adaptability

Corrosion protection grade C4 (ISO 12944).

Features rainproof covers and anti-icing heaters, ensuring stable operation in harsh conditions (humidity >90%, temperatures from -25°C to +45°C).

Multi-Condition Safety Protections

Integrated overload limiters, wind speed alarms (>12 m/s auto-lock), rail deviation detection, and dual braking systems, compliant with GB/T 14405 safety standards.

Typical Applications of hydroelectric power station gantry cranes

Gate Operations: Vertical/horizontal lifting and tilting installation of flat gates and radial gates (e.g., maintenance of spillway gates in large dams).

Turbine Installation: Indoor lifting and positioning of rotors for hydroelectric generator units (single-unit weight: 300–800 tons).

Emergency Response: Rapid opening/closing of emergency gates during flood seasons (e.g., emergency closure force up to 2000 kN for deep outlet gates).

Auxiliary Maintenance: Hoisting trash rack debris removal equipment and assembling penstock welding platforms.

Restrictions: Prohibited from lifting molten metals; regular inspection of track settlement required (permissible error ≤ 1/1000 of span).

Port Cranes

Port Cranes  Overhead Cranes

Overhead Cranes  Gantry Cranes

Gantry Cranes  Rubber-Tired Gantry Cranes

Rubber-Tired Gantry Cranes  Jib Cranes

Jib Cranes  Bridge Beam Launcher

Bridge Beam Launcher  Light-duty Cranes

Light-duty Cranes  Electric Hoists

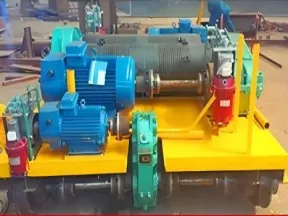

Electric Hoists  Electric Winch

Electric Winch  Electric Flat Car

Electric Flat Car  Crane Accessories

Crane Accessories  Hydraulic Lifting Platform

Hydraulic Lifting Platform  General Manufacturing

General Manufacturing  Heavy Machinery Manufacturing

Heavy Machinery Manufacturing  Bulk Cargo Yard

Bulk Cargo Yard  Metallurgical Industry

Metallurgical Industry  Power Industry

Power Industry  Hydraulic Engineering

Hydraulic Engineering  Railway/Rail Transit

Railway/Rail Transit  Port Terminal

Port Terminal  Construction and Engineering

Construction and Engineering  Shipbuilding

Shipbuilding  Waste Recycling

Waste Recycling