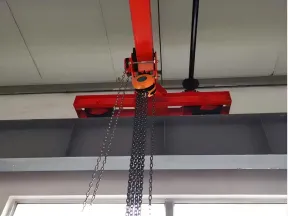

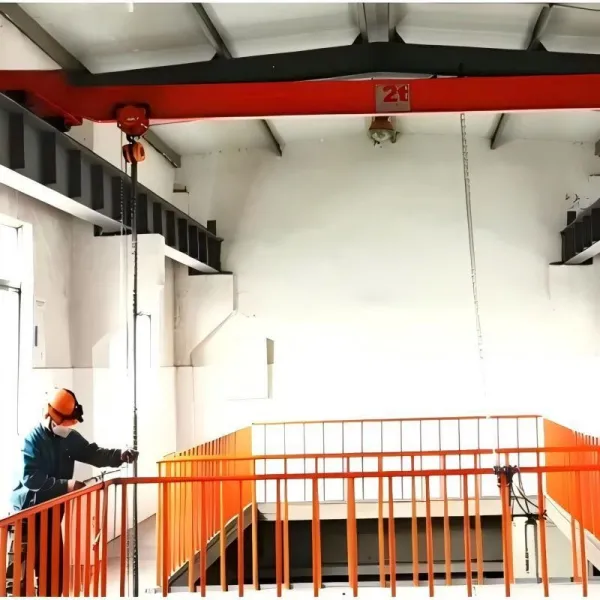

SL Type Manual Single Girder Bridge Crane is a fundamental lifting equipment characterized by its simple structure, cost-effectiveness, easy maintenance, and high safety reliability. Its greatest advantages lie in its independence from electricity and extremely low operational costs, albeit at the expense of lower efficiency and higher manual labor intensity.

Therefore, when selecting this equipment, practical production needs, operational frequency, budget constraints, as well as requirements for efficiency and automation levels should be thoroughly considered to determine whether it is the optimal choice for your application.

Feature of the SL Type Manual Single Girder Bridge Crane:

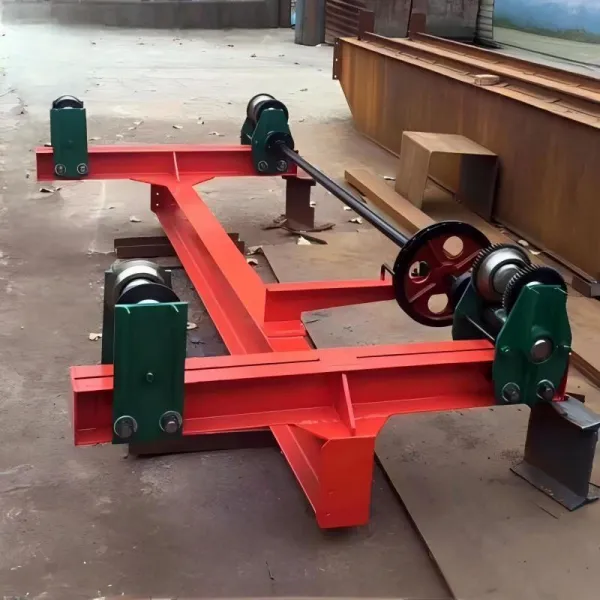

1.Simple Structure and Low Cost: Composed mainly of rolled steel shapes (such as I-beams) and simple drive mechanisms, it lacks complex motors, control systems, or power supply systems. As a result, both manufacturing and purchasing costs are significantly lower than those of electric cranes.

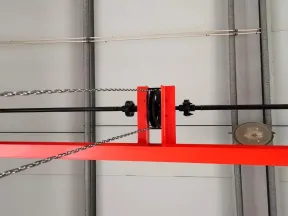

2.Easy Maintenance and Low Failure Rate: With no electrical components or intricate mechanical transmission parts, maintenance is straightforward. Regular lubrication and track inspections are usually sufficient, minimizing potential failure points.

3.No External Power Required, Energy-Saving and Eco-Friendly: It consumes no electricity and can be used in any location with suitable installation conditions, eliminating power supply concerns. It is highly energy-efficient.

4.Safe Operation and Low Skill Requirements: Movement speed is entirely manually controlled, resulting in slow and smooth operation with minimal shock or sway. Operators do not require special certification and can perform tasks after basic training.

5.Easy Installation: It has low requirements for workshop structure support. Tracks are typically mounted on ground-based supports or low piers, avoiding the need for complex overhead conductor systems or heavy-duty workshop support structures.

Application of the SL Type Manual Single Girder Bridge Crane:

1.Locations Without Power or with Limited Power Supply: Such as warehouses in remote areas, temporary worksites, and outdoor operation sites.

2.Workshops or Warehouses with Low Frequency and Light Loads: Examples include repair workshops, mold storage areas, spare parts warehouses, and assembly shops, where it is used for occasional lifting of maintenance parts, molds, or equipment.

3.Budget-Constrained Small and Medium-Sized Enterprises: For startups or small processing plants with limited investment and low efficiency requirements, it offers the most cost-effective solution for mechanized material handling within workshops.

4.As Auxiliary Lifting Equipment: In large workshops, alongside mainstream electric overhead cranes, a manual single-girder crane may be installed in corners or auxiliary areas to handle scattered, non-critical lifting tasks, saving energy and reducing equipment wear.

Port Cranes

Port Cranes  Overhead Cranes

Overhead Cranes  Gantry Cranes

Gantry Cranes  Rubber-Tired Gantry Cranes

Rubber-Tired Gantry Cranes  Jib Cranes

Jib Cranes  Bridge Beam Launcher

Bridge Beam Launcher  Light-duty Cranes

Light-duty Cranes  Electric Hoists

Electric Hoists  Electric Winch

Electric Winch  Electric Flat Car

Electric Flat Car  Crane Accessories

Crane Accessories  Hydraulic Lifting Platform

Hydraulic Lifting Platform  General Manufacturing

General Manufacturing  Heavy Machinery Manufacturing

Heavy Machinery Manufacturing  Bulk Cargo Yard

Bulk Cargo Yard  Metallurgical Industry

Metallurgical Industry  Power Industry

Power Industry  Hydraulic Engineering

Hydraulic Engineering  Railway/Rail Transit

Railway/Rail Transit  Port Terminal

Port Terminal  Construction and Engineering

Construction and Engineering  Shipbuilding

Shipbuilding  Waste Recycling

Waste Recycling