A Full Span Launching Gantry refers to a specialized gantry used for the integral hoisting and erection of a complete precast box girder or T-beam span. It is capable of hoisting and installing an entire precast girder for one span in a single operation. Its primary applications are in high-speed railways, highways, and bridge construction projects.

A Full Span Launching Gantry is construction equipment used to erect precast concrete girders on piers. During operation, the entire main girder of the machine is supported on the two piers at the front and rear. After completing the erection for one span, the entire machine must move forward to proceed with the next span. This type offers stable support and strong adaptability, serving as fundamental equipment in bridge construction.

Main Features of Full Span Launching Gantry:

It can hoist or slide-install an entire-span precast girder in one operation, enabling fast construction speed.

It is commonly used for bridges with equal span lengths and multiple continuous spans.

It requires piers and temporary support piers with substantial load-bearing capacity.

It is suitable for scenarios with flat terrain and favorable transport conditions.

Main Applications of Full Span Launching Gantry:

High-speed railway bridges

Highway bridges

Sea-crossing or river-crossing bridges

Product Details

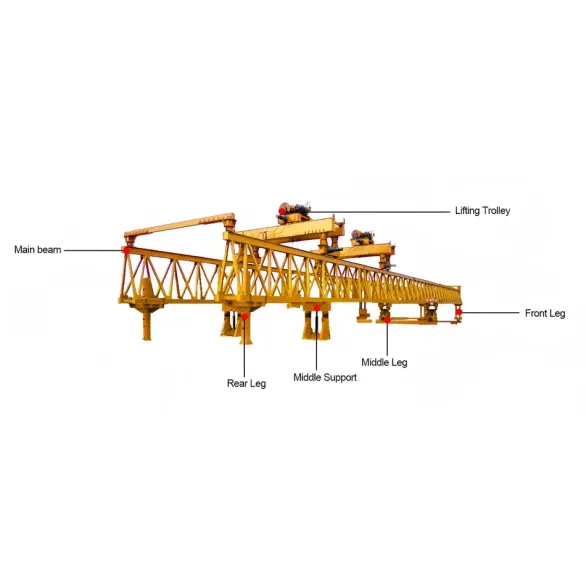

Main Girder/Main beam: The core load-bearing component, typically a box girder (used for high-speed rail) or a truss girder.

Support Legs: Comprising front, middle, and rear legs, which support and anchor the entire machine on piers or the bridge deck.

Lifting Trolley: Moves along the main girder and is used for hoisting the integrally precast box girder or T-beam.

Travel System: Drives the entire machine to move along the bridge axis (span crossing).

Launching Nose System: Some models are equipped with a launching nose (or front guiding beam) to assist the gantry in safely traversing the span to be erected.

Hydraulic and Electrical Control System: Powers all movements, enabling synchronous control, precise positioning, and intelligent monitoring.

Port Cranes

Port Cranes  Overhead Cranes

Overhead Cranes  Gantry Cranes

Gantry Cranes  Rubber-Tired Gantry Cranes

Rubber-Tired Gantry Cranes  Jib Cranes

Jib Cranes  Bridge Beam Launcher

Bridge Beam Launcher  Light-duty Cranes

Light-duty Cranes  Electric Hoists

Electric Hoists  Electric Winch

Electric Winch  Electric Flat Car

Electric Flat Car  Crane Accessories

Crane Accessories  Hydraulic Lifting Platform

Hydraulic Lifting Platform  General Manufacturing

General Manufacturing  Heavy Machinery Manufacturing

Heavy Machinery Manufacturing  Bulk Cargo Yard

Bulk Cargo Yard  Metallurgical Industry

Metallurgical Industry  Power Industry

Power Industry  Hydraulic Engineering

Hydraulic Engineering  Railway/Rail Transit

Railway/Rail Transit  Port Terminal

Port Terminal  Construction and Engineering

Construction and Engineering  Shipbuilding

Shipbuilding  Waste Recycling

Waste Recycling